Welcome to this comprehensive guide on plugging a bowling ball. If you are an avid bowler, chances are you’ve experienced the need to repair or repurpose your bowling ball, and plugging is a key aspect of that process.

The purpose of this blog post is to equip you with the necessary knowledge and best practices to handle the process of plugging a bowling ball. From understanding the intricacies involved in the process to careful aftercare, we’ve got you covered.

This guide aims to empower you, the reader, with insights and recommendations to maintain your bowling ball’s performance and extend its lifespan.

As always, remember that while this guide serves as a comprehensive reference, actual circumstances may vary, and personal consultation with a professional is recommended. Let’s roll into it!

Understanding Bowling Ball Plugging

Plugging a bowling ball refers to the process of filling up previously drilled holes in the ball. This is typically done when a bowler decides to re-drill their bowling ball for a better grip or a change in ball motion.

The process involves using a special plug compound to fill the holes so that they can be re-drilled in accordance with the bowler’s current requirements. This procedure extends the life of the bowling ball and enables the bowler to customize the ball to better suit their bowling style and technique.

Why You May Need to Plug a Bowling Ball

There are several reasons why a bowler might need to plug their bowling ball. One of the most common reasons is to adjust the ball’s performance characteristics.

Over time and with regular use, a ball’s drilled holes may become worn or otherwise compromised, affecting the ball’s roll and overall performance. Plugging allows these holes to be filled and re-drilled, which can restore or even improve the ball’s performance.

Another reason could be due to a change in the bowler’s grip or throwing style. If a bowler’s technique changes, the existing hole positions on the ball may no longer provide an optimal grip. In this case, plugging and re-drilling the holes can offer a more comfortable and effective grip.

Additionally, if a used ball is purchased or received, the new owner will likely need to have the ball plugged and re-drilled to fit their specific hand size and bowling style.

Revitalizing Your Game: A Case Study on the Benefits of Plugging Your Bowling Ball

Let’s consider the example of a professional bowler, John Doe. John, an experienced player, had been using the same bowling ball for several seasons.

He noticed a gradual decline in his scores and realized his ball’s performance wasn’t as consistent as it once was.

The finger holes had begun to widen due to continuous use, affecting his grip and, subsequently, his throwing accuracy. Instead of immediately opting for a new bowling ball, John decided to have his old one plugged and re-drilled at a reputable pro shop.

The result was a rejuvenated bowling ball that fit his grip perfectly, improving his performance and saving him the cost of a brand-new ball. This case study illustrates how plugging and re-drilling can prolong the lifespan of your bowling ball and enhance your game.

Case Study: Jane Doe – Adjusting to Hand Shape Changes Through Bowling Ball Plugging and Re-Drilling

When it comes to professional bowlers, precision, and comfort in their equipment can make a world of difference in their performance.

Take, for instance, the case of Jane Doe, a seasoned professional bowler. Jane had been using the same bowling ball for years, perfectly accustomed to its weight and feel. However, she started experiencing discomfort while gripping the ball due to changes in her hand shape over time.

Instead of switching to a new ball, Jane opted to have her bowling ball plugged and re-drilled. This allowed her to maintain the familiar weight and balance of her old ball, while ensuring a comfortable, precise fit for her hand. Jane’s case clearly illustrates why plugging and re-drilling a bowling ball can be a preferred choice over buying a new one for many professional bowlers.

The Process of Plugging a Bowling Ball

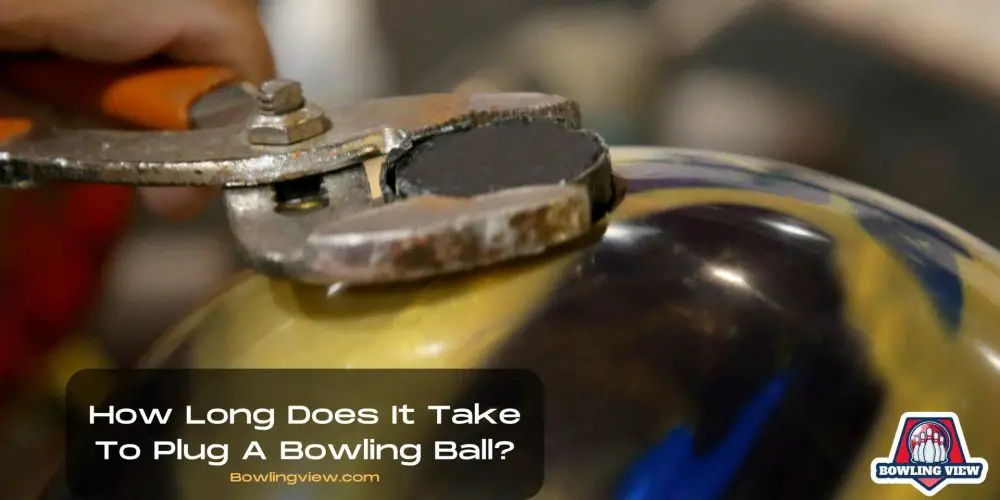

The process of plugging a bowling ball can be broken down into several key steps:

- Cleaning the Ball: Initially, the ball is thoroughly cleaned to remove any oil, dirt, or residue. This ensures the plug material adheres properly to the ball surface.

- Marking and Drilling Out Old Holes: The existing holes on the ball are marked and then drilled out. This is done carefully to avoid damaging the ball.

- Filling the Holes: A special plug material is mixed and poured into the drilled-out holes. This material needs to be the same density as the ball for consistent performance.

- Curing Process: The ball is then left to cure for a certain period. This allows the plug material to harden and become a permanent part of the ball.

- Surface Finishing: Once the plug material has cured, the ball is sanded and polished. This makes the surface of the ball smooth and restores its original appearance.

- Re-Drilling the Holes: The ball is then re-drilled according to the bowler’s specifications. The new holes must be in the correct location to suit the bowler’s grip and throwing style.

This is a detailed process that requires precise workmanship and a good understanding of bowling ball dynamics. It is important to have this work done by a professional q pro ship to ensure the best results.

Factors Affecting the Time it Takes to Plug a Bowling Ball

Exploration of the different factors that influence the duration it takes to plug a bowling ball.

Several factors impact the time it takes to plug a bowling ball effectively.

- Plug Material Type: Different materials have different curing times. Some materials may harden in just a few hours, while others may need a full day or more.

- Temperature and Humidity: Environmental conditions can influence the curing process. A hot and dry environment tends to speed up the process, whereas a cold or humid environment can slow it down.

- Size and Number of Holes: Larger or multiple holes will require more time since they need more material to fill and hence more time to cure.

- Skill and Experience of the Technician (Pro or Beginning Bowlers): A highly skilled and experienced technician can work more efficiently, potentially reducing the time required to plug the ball.

These factors underline the importance of allowing a professional to handle the delicate process of plugging your bowling ball, ensuring the job is done correctly and in a timely manner.

Average Time to Plug a Bowling Ball

On average, plugging a bowling ball can take anywhere from 24 to 72 hours. This time frame accounts for the meticulous job of filling the holes, allowing the plug material to cure, and then resurfacing and polishing the ball. However, as mentioned earlier, factors such as the type of plug material, temperature and humidity, size and number of holes, and the technician’s skill level can significantly affect this average timeline. Therefore, it’s always advisable to consult with your technician about the specific time frame for your bowling ball.

Post-Plugging Aftercare: Important Considerations for Optimal Results

Following a few key steps can ensure that the plug material bonds properly and that your ball performs at its best.

- Allow Ample Curing Time: Even if the exterior of the plug feels hard, the interior may still be curing. It’s crucial to let the ball sit undisturbed for the full recommended curing period to achieve optimal results.

- Avoid Extreme Temperatures: Keep the ball at room temperature after plugging. Too cold or hot conditions can cause the plug material to contract or expand, leading to potential cracks or an improper fit.

- Regular Inspection: Regularly inspect the plugged area for signs of damage or wear. If you notice any changes, take your ball to a professional for assessment.

- Gradual Usage: Start using your plugged ball gradually. Begin with lighter throws before moving on to full-force strikes. This eases the ball back into play and helps identify any issues early.

Remember, proper aftercare can significantly extend the life of your plugged bowling ball and enhance its performance. Always consult with a professional if you have any concerns or questions about the aftercare process.

Conclusion

In conclusion, the process of plugging a bowling ball is a detailed one and demands meticulous care. It is important to understand the curing time and avoid exposing the plugged ball to extreme temperatures to prevent potential damage.

Regular inspection and gradual usage are also key to maintaining the ball’s performance post-plugging. Attention to proper aftercare can significantly extend the life of your plugged bowling ball and enhance its performance.

Remember, professional help is always advisable whenever you have questions or concerns about the process. This guide serves as a comprehensive reference, but actual circumstances may vary and personal consultation remains crucial.

FAQs

Below, you’ll find a comprehensive list of Frequently Asked Questions (FAQs) designed to address any uncertainties you may have about the processes of re-drilling, plugging, and maintaining your bowling ball.

We aim to cover all aspects, thereby providing you with the necessary knowledge to make informed decisions.

The process of plugging and re-drilling a bowling ball can take anywhere from 24 to 72 hours. This time frame includes the time needed for the plug material to set and cure before the ball is re-drilled.

Unless you’re an experienced bowler with knowledge of bowling ball mechanics, it’s advisable to visit your local pro shop for a bowling ball re-drilling. The chances of precise re-drilling at home with standard tools are low, and you may damage the coverstock or core of the ball.

The pros of plugging a bowling ball include extending its lifespan, making use of a used bowling ball, and adjusting the finger and thumb holes to your comfort. The cons include potential imbalance of the ball, alteration of the ball’s original core dynamics, and possibility of plug failure.

A common plugging question asked is whether plugging and re-drilling bowling balls impacts the performance. The answer to this question is yes, because re-drilling can alter the original layout, balance, and weight of the ball, and therefore could affect its performance.

Yes, you can plug and re-drill a resin coverstock bowling ball. However, it’s important to note that the chemistry of the coverstock may be affected, potentially changing the ball’s reaction on the lanes.

If you re-drill your bowling ball and it doesn’t fit properly, you’ve likely made an error in measurements. In such a case, it’s best to return to your pro shop for another adjustment.

Yes, it’s crucial to properly plug or fill bowling ball holes before re-drilling. If not done right, the ball could get extensively damaged during re-drilling.

You should consider buying a new bowling ball if your old ball is significantly worn out, cracked, or if the core is showing.

If there’s a drastic change in the ball’s performance or if it has been plugged and re-drilled several times, a new bowling ball would be a better option.

Yes, it is possible to only re-drill the thumb hole of your bowling ball if you’re comfortable with the current position of the finger holes but need a minor tweak to the thumb hole for a better fit and grip.

However, any re-drilling should be done at a pro shop to ensure accuracy.

Specialized bowling ball plug material, which is often a type of epoxy resin, should be used to fill bowling ball holes.

The plug material usually comes in a two-part system that, when combined and cured, mimics the hardness and texture of the original bowling ball.